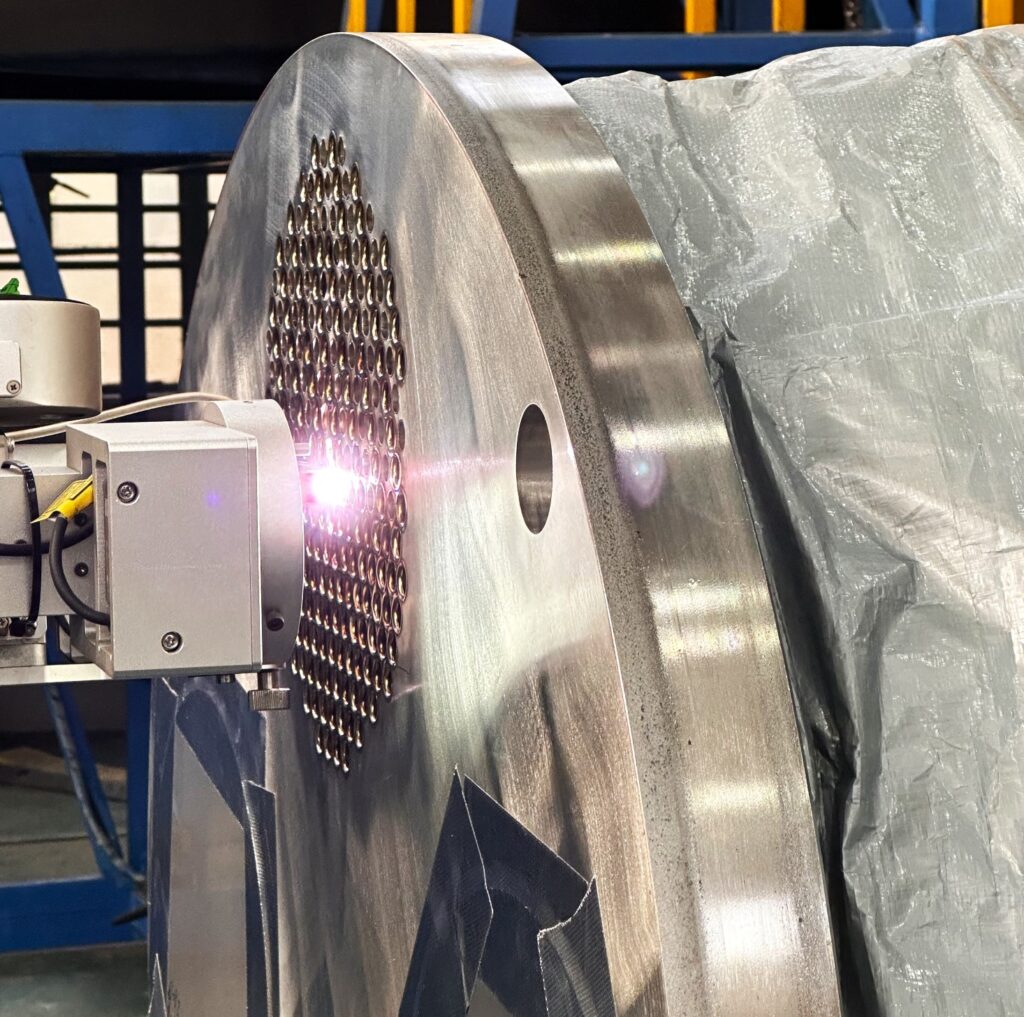

Nectis provides Spiral Tube Heat Exchangers (STHE) to refining, petrochemicals, gas processing industries, and power.

Thanks to patented design and manufacturing techniques, this technology features a unique track record of thermal efficiency and operational robustness. STHE exchangers are fabricated according to ASME Section VIII and certified with either a U or U2 stamp. This mark is a guarantee of the quality of the Spiral Tube Heat Exchanger.

Thanks to their geometry and perfect counter-current operation, Spiral Tubes Heat Exchangers allow maximum heat recovery and minimization of OPEX and ultimately improve their energy efficiency.

Spiral Tube Heat Exchangers (STHE) proven ability to handle heavy or fouling refinery streams opens up a wide array of energy efficiency opportunities for new process units as well as existing assets.

Nectis technology’s comes with a comprehensive range of services allowing industries to get full support.

The heat transfer efficiency is 2 to 3 times higher than conventional shell and tube heat exchangers as the spiral tube design improves the fluid flow regime by creating high turbulence inside and outside the tubes. This allows for a pinch point as low as 2°C reducing consequently the hot and cold approach temperatures of the exchanger.

The smooth and continuous flow path of the spiral tubes design minimizes pressure drop, which reduces energy consumption and improves efficiency. Moreover as one STHE can replace several horizontal or vertical exchangers, the overall dP of the system is minimized.

Spiral Tubes heat exchangers have a high surface area to volume ratio. Only one exchanger can replace multiple horizontal or vertical exchangers, saving on installation and capital cost for both new units and revamping projects.

It can offer a heat exchange up to 30,000 m² for reforming and aromatic processes, and up to 10,000 m² for hydroprocessing units in a single piece.

The special design of the tube bundle, absorbing thermal dilatation as a spring, is reducing the mechanical stress on the tubes. This robust and tolerant design allows for:

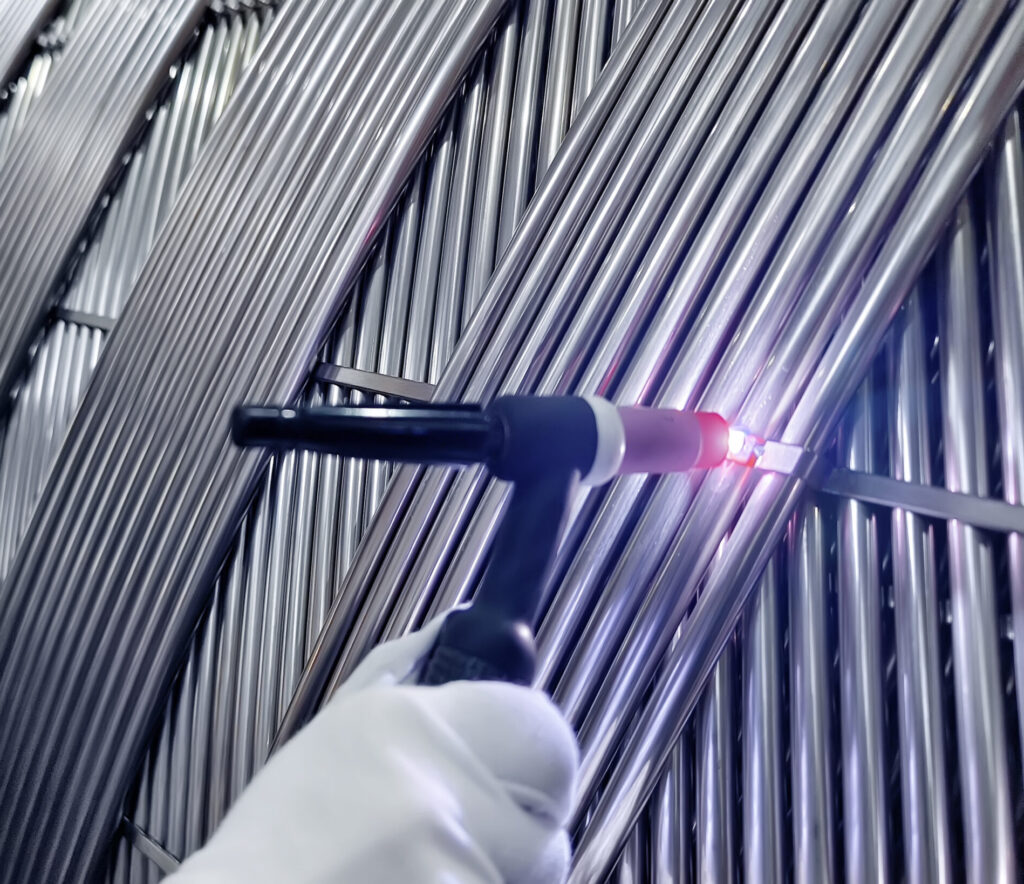

On the shell side, the high turbulence created by the pulse-surge collision flow pattern and the absence of a stagnant zone greatly reduce the possibility of fouling.

On the tube side, the helix-pattern flow creates a secondary flow which increases the shear force. This effect, added to the very low surface roughness, gives an anti-fouling and self-cleaning design.

Nectis provides a unique technology and outstanding services to help its customers to decarbonize their units.