The process industries are at an inflection point, driven to find smart solutions to address supply and demand challenges while reducing their environmental impact.

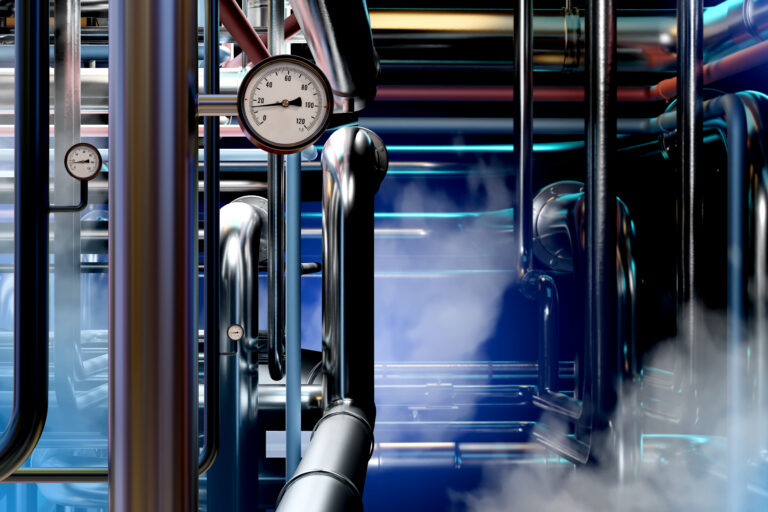

The heat transfer technology introduced by Nectis is opening up new opportunities for various markets and industries willing to develop decarbonization projects.

At Nectis, we are committed to helping the refining, petrochemical, gas, pharmaceutical and power industries improve their production processes. With the Spiral Tube Heat Exchanger, industries can optimize their performances and reduce their fuel and energy consumption while meeting the latest environmental regulations.

The supply of critical equipment for industrial sites implies the responsibility of ensuring safe and efficient operation, prioritizing high quality and robustness, while effectively managing costs.

By choosing Nectis, a joint venture dedicated to the promotion and sale of Spiral Tubes Heat Exchangers, industries are investing in a high-performance and reliable heat transfer solution, enabling high-yield production with guaranteed process performances.

Nectis equipment contributes to a significant reduction of capital and operational costs. Their compact design allows them to replace multiple horizontal or vertical exchangers, leading to a reduction in installation and capital costs. The high-efficiency design optimizes operating costs by reducing unit fuel and energy consumption. Designed to last, these efficiency-proven units are easy to maintain due to their low fouling characteristics.

With Spiral Tube Heat Exchanger technology, Nectis is able to support various industries using the following applications.

PRODUCT CHARACTERISTICS:

High efficiency, low pressure drop, mechanical robustness.

Recomended by UOP and AXENS.

15 years of experience, more than 150 references

(+) 30 000 m² in one unit

Less piping, flange, gaskets

Robustness, no limit during upset conditions, no leakage

Less piping, flange, gaskets

Mechanical cleaning on the tube side

Chemical cleaning on shell side and tube side

Easy and well known cleaning procedures

High efficiency, low HAT

Less fuel consumption, low emissions

PRODUCT CHARACTERISTICS:

Adapted metallurgy, high efficiency, easily cleanable.

Recommended by AXENS.

20 years experience, more than 200 references.

No leakage

Statistics of our references in low sulfur units

Chemical cleaning on tube and shell side, mechanical cleaning on tube side

Cleaning similar to well known tubular exchangers

No limitation in cracked feedstock

Less fouling than conventionnal S&T

Bundle inside a pressure vessel. Can sustain high differential pressure

Reference list with high pressure & temperature units

Experience with various metallurgy. Overlay cladding on the shell side.

Large trouble free database

High efficiency, low HAT

Less fuel consumption, low emissions, heater can be shut down during normal operations

PRODUCT CHARACTERISTICS:

Adapted metallurgy, high efficiency, easily cleanable.

Recommended by UOP.

More than 50 references.

Large surface in one single exchanger

Less piping, flange, gaskets

Adapted metallurgy

Stainless steel pressure vessel

Specific fabrication method

Inner bore welding of the tubes to the tubesheet to have a crevasse free design

Chemical cleaning on tube and shell side, mechanical cleaning on tube side

Cleaning similar to well known tubular exchangers

Less fouling than conventionnal S&T

High efficiency, low HAT

Less fuel consumption, low emissions, heater can be shut down during normal operations

PRODUCT CHARACTERISTICS:

Multi fluid, anti fouling, easy to clean.

More than 40 references.

Large surface in one single exchanger

Less piping, flange, gaskets

Chemical cleaning on tube and shell side, mechanical cleaning on tube side

Cleaning similar to well known tubular exchangers

Less fouling than conventionnal S&T

Multifluid design

Can replace multiple exchanger and reduce the plot plan and complexity of the unit.

Nectis provides a unique technology and outstanding services to help its customers to decarbonize their units.